Наши услугиOur servicesXizmatlar

Чем мы занимаемсяWhat we doBizning faoliyatimiz

Парманкулов Икрамжон ИсамиддиновичParmankulov Ikramjon IsamiddinovichParmankulov Ikramjon Isamiddinovich

Генеральный директорGeneral DirectorBosh direktor

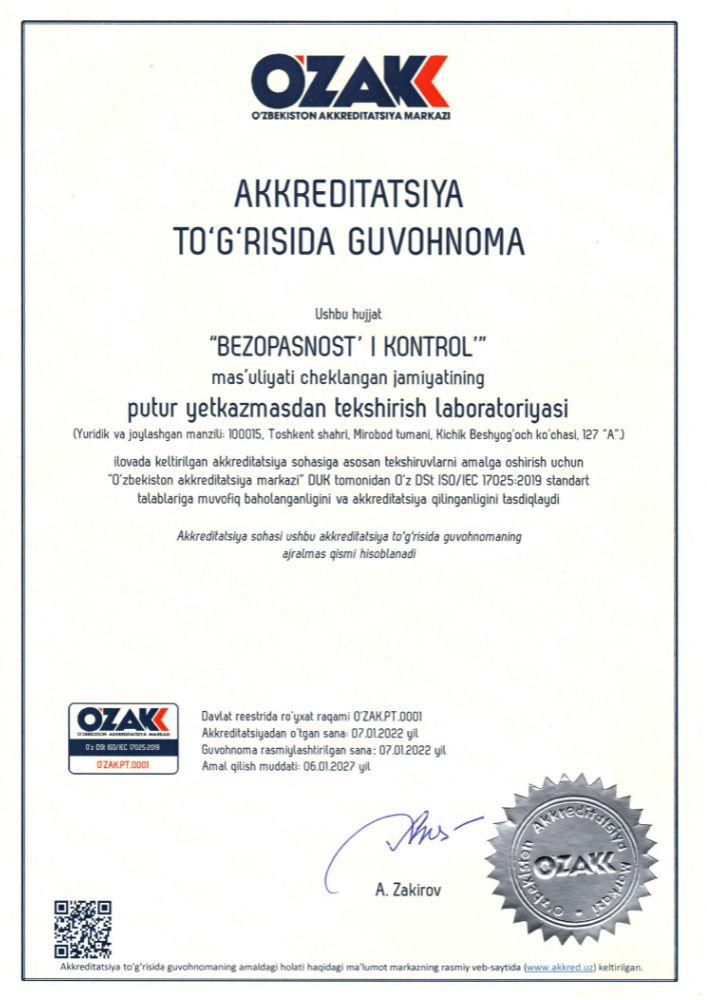

Лицензируемые услугиLicensed servicesLitsenziyalanuvchi xizmatlar

Услуги Нашей компании включают виды деятельности, на осуществление которых на территории Республики Узбекистан требуется получение лицензиий Our company's services include activities that require licenses on the territory of the Republic of Uzbekistan Kompaniyamizning xizmatlari sirasiga O‘zbekiston Respublikasi hududida amalga oshirish uchun litsenziya olish talab etiladigan faoliyat turlari kiradi.

Наши клиентыOur clientsBizning mijozlar

Всех наших заказчиков мы считаем полноправными партнерами и со многими из них поддерживаем взаимовыгодное сотрудничество в течение многих лет. Гарантией качества наших работ является профессионализм сотрудников и хорошая научно-производственная база. Возможность решения комплекса задач позволяет сэкономить время и деньги. Мы с нетерпением ожидаем расширения нашей клиентской базы и верим что Ваша организация станет ее частью.

We consider all our clients as full-fledged partners and we have been maintaining mutually beneficial cooperation with many of them for years. The guarantee of the quality of our work is the professionalism of our employees and a good research and production base. Our ability to solve complex tasks saves time and money to our clients. We look forward to expansion of our clientele and expect your organization to become part of it as well.

Biz barcha mijozlarimizni to‘laqonli hamkorlar deb bilamiz va ularning ko‘pchiligi bilan ko‘p yillardan buyon o‘zaro manfaatli hamkorlik qilib kelamiz. Xodimlarimizning professionallizmi va yaxshi ilmiy-ishlab chiqarish bazasi ishimiz sifatining kafolatidir. Murakkab muammolarni hal qilish qobiliyati vaqt va pulni tejaydi. Umid qilamizki, bu ro‘yxat o‘sib boradi va sizning tashkilotingiz ham bizning hamkorimizga aylanadi.